Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Sheet metal bending personnel essential skills

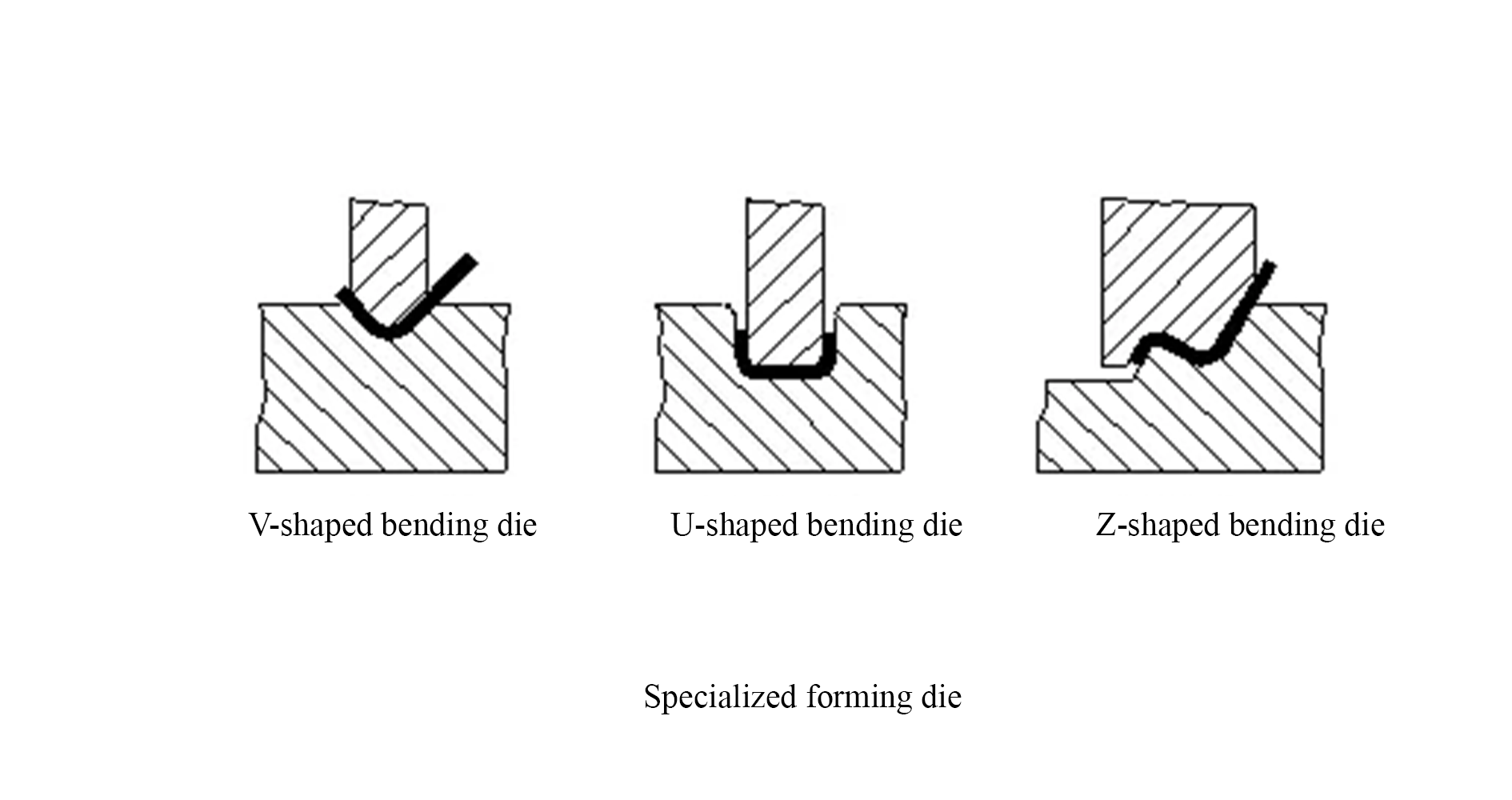

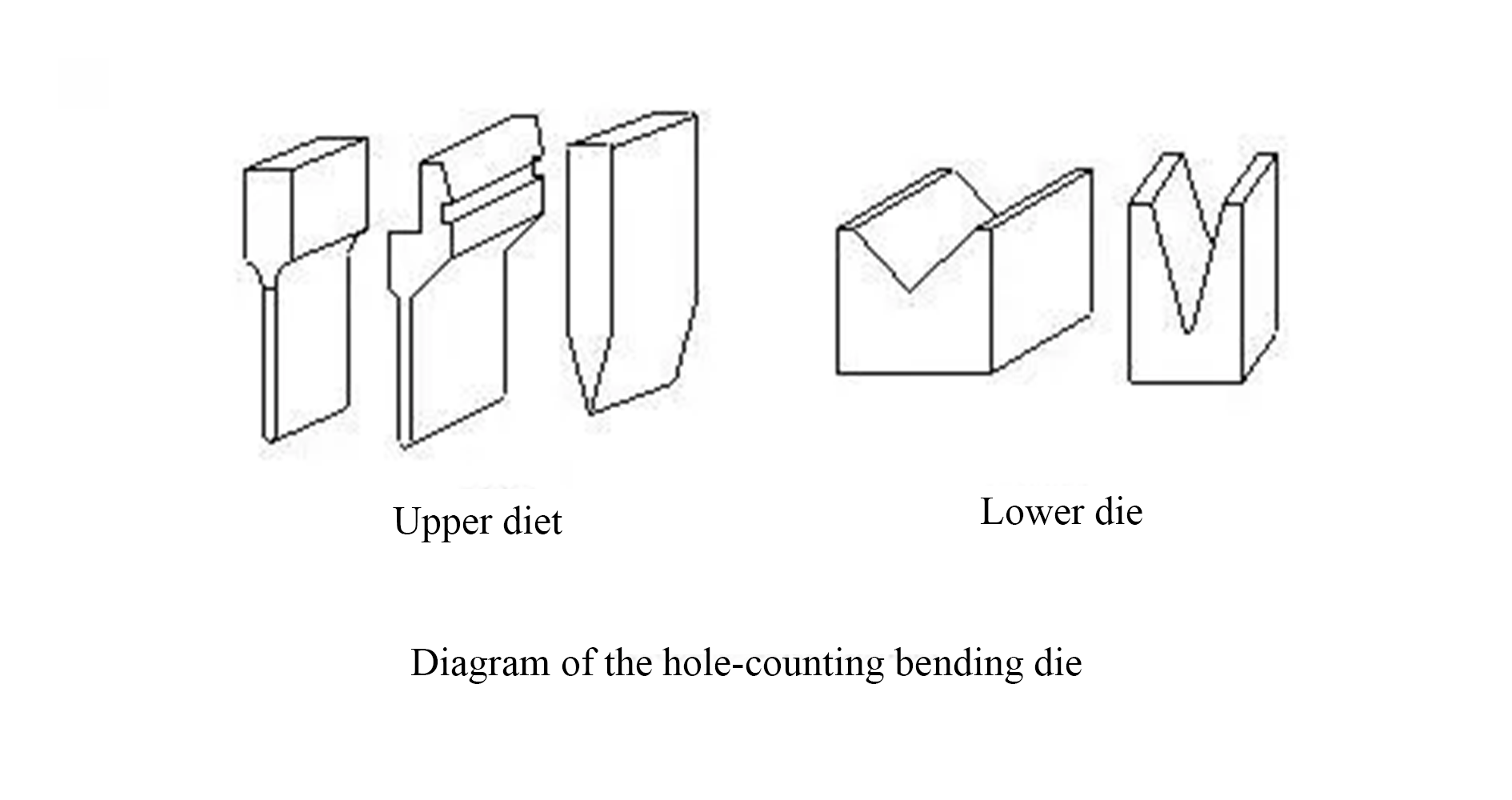

Commonly used bending molds, as shown below. In order to extend the life of the mold, the parts are designed with rounded corners wherever possible.

Too small bending height, that is, the use of bending molds are not conducive to forming, general bending height L ≥ 3t (including wall thickness).

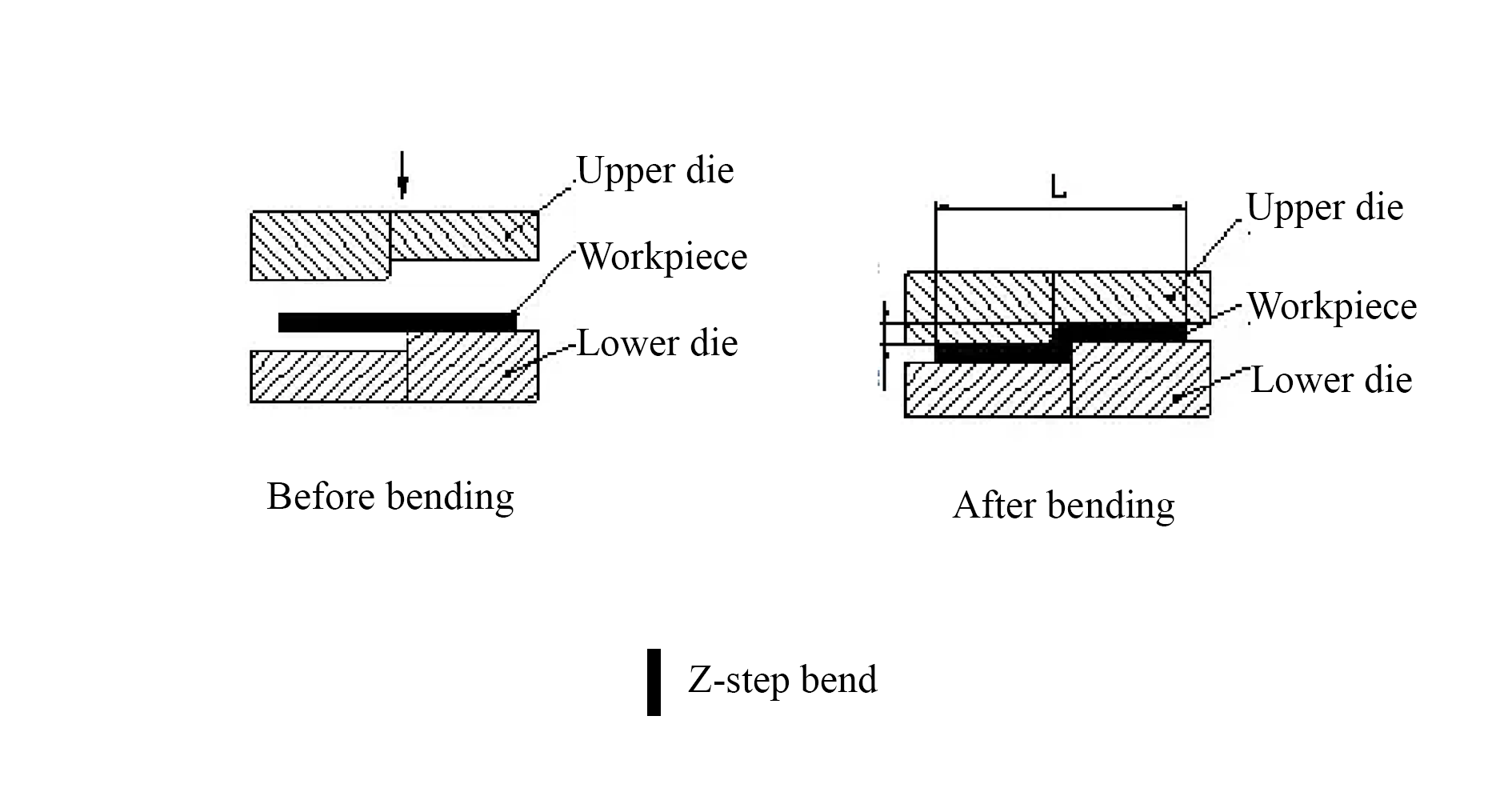

Processing of steps

Some of the lower height of the sheet metal Z-shaped step bending, processors tend to use simple molds in the punch press or hydraulic press, the batch is not large can also be processed in the bending machine with the segment difference mold, as shown in the figure below. However, its height H can not be too high, generally should be in the (0 ~ 1.0) t. If the height of (1.0 ~ 4.0) t, according to the actual situation to consider the use of plus unloading structure of the mold form.

This kind of mold step height can be adjusted by adding shims, so the height H is arbitrarily adjustable, but there is a disadvantage that the length L size is not easy to guarantee the verticality of the vertical edge. If the height H size is very large, we should consider bending on the bending machine.

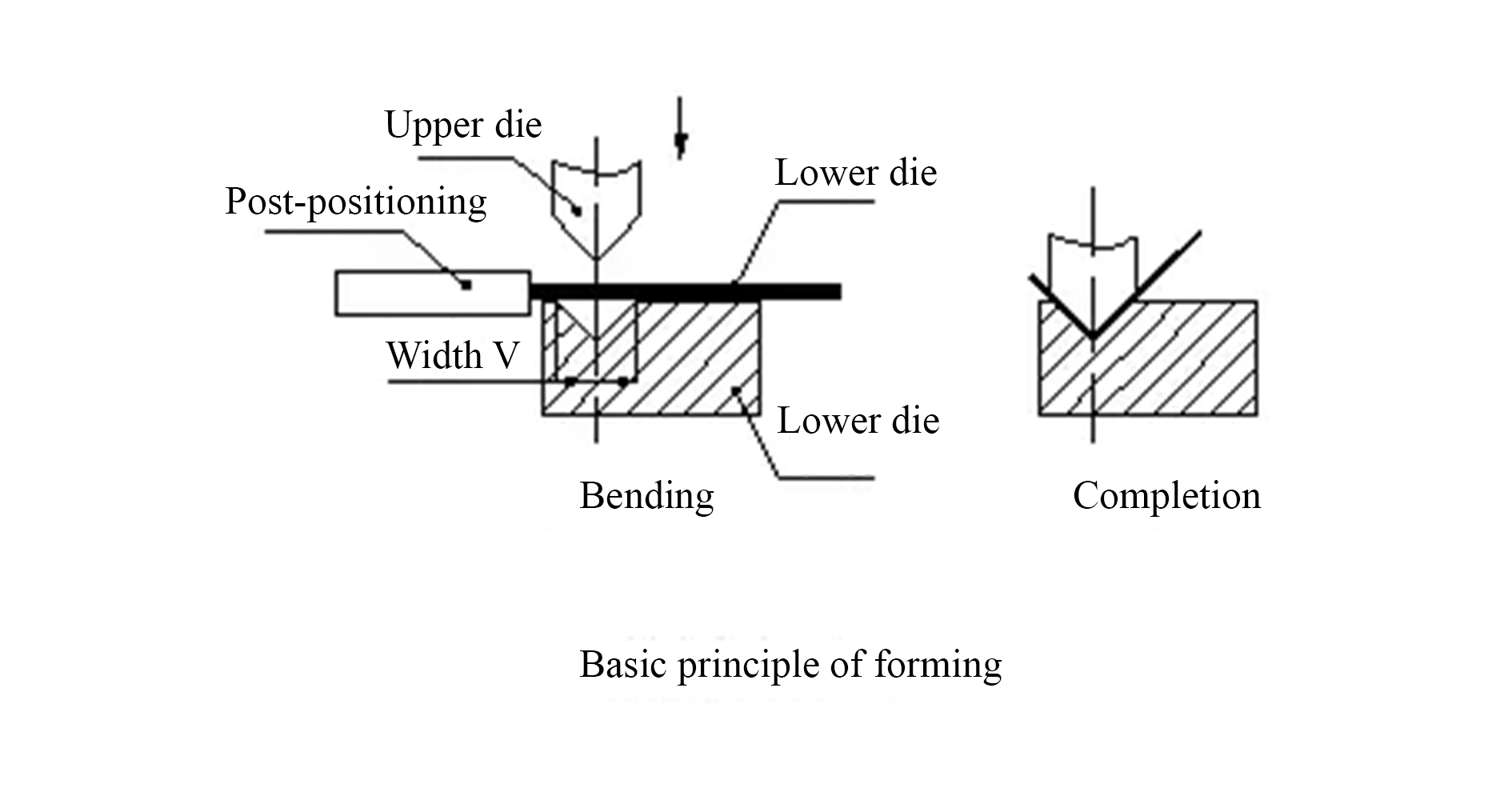

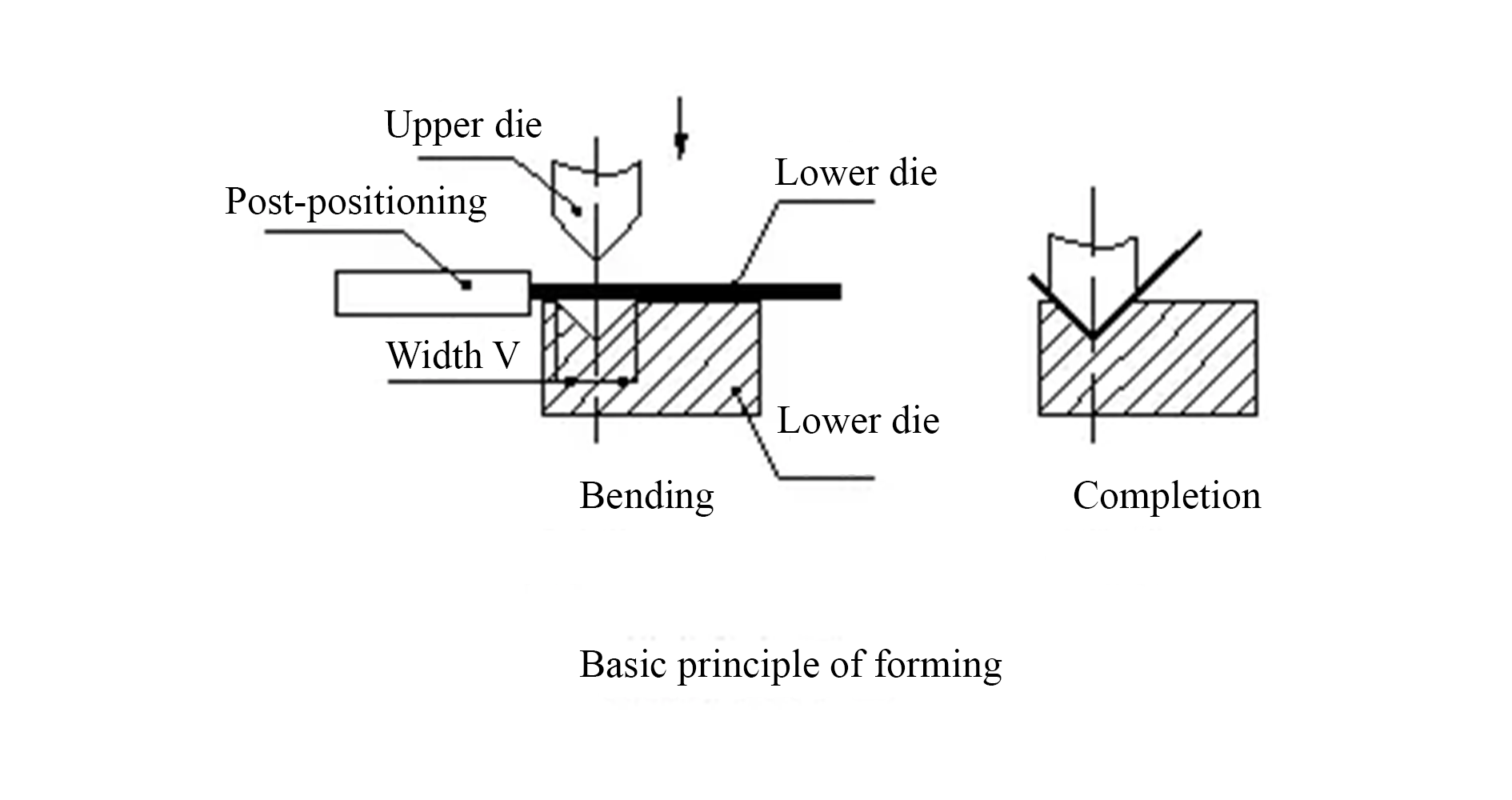

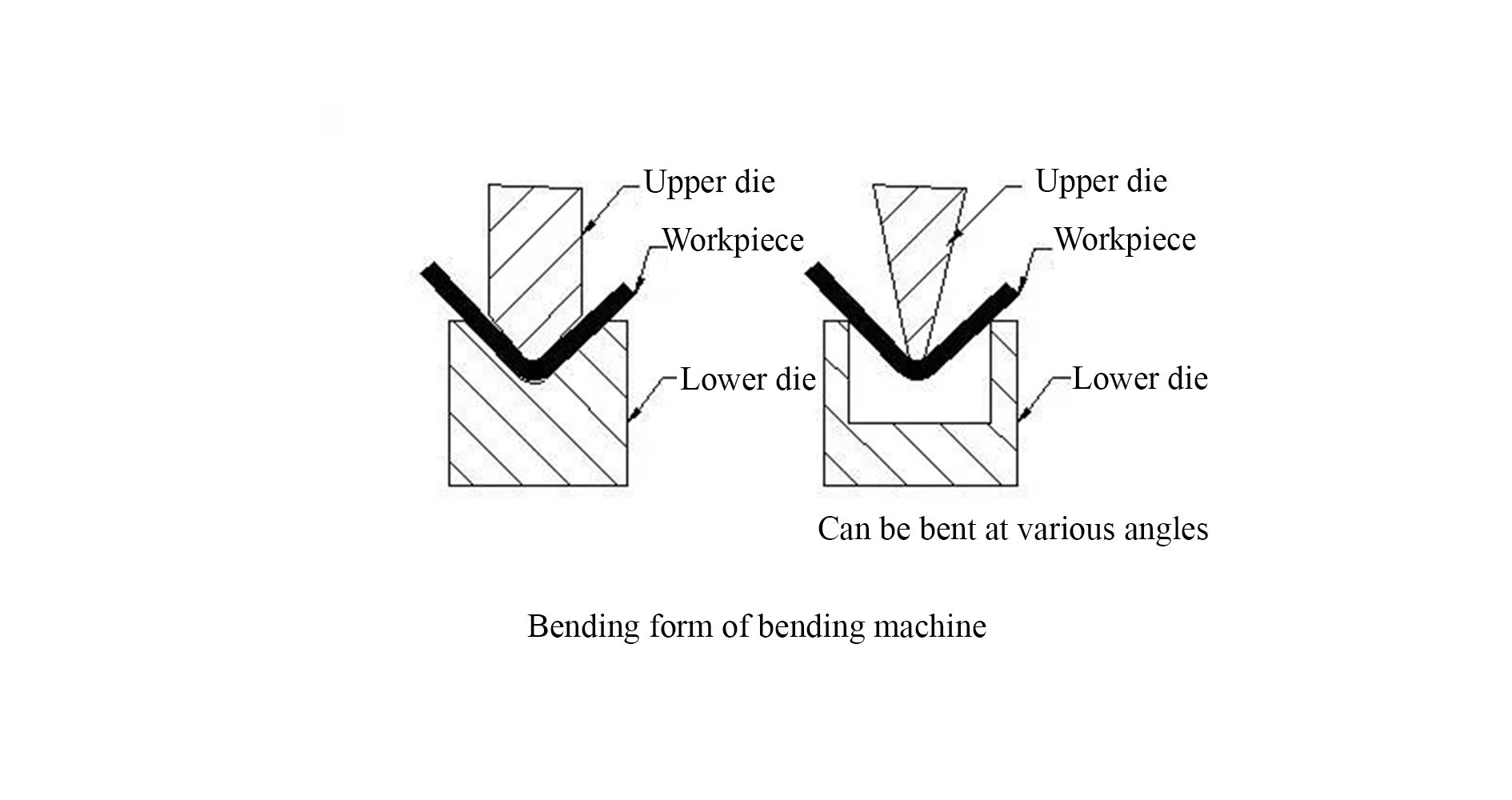

Bending machine is divided into ordinary bending machine and CNC bending machine two kinds. Due to the high precision requirements, bending shape irregularities, sheet metal bending of communications equipment is generally used in CNC bending machine bending, the basic principle is to use the bending machine bending knife (upper mold), V-shaped groove (lower mold), the sheet metal parts for bending and forming.

Advantages: easy to clamp, accurate positioning, fast processing speed;

Disadvantages: low pressure, can only process simple molding, lower efficiency.

Basic Principles of Molding

The basic principle of molding is shown below:

Bending knife (upper mold)

The form of bending knife as shown in the figure below, the processing is mainly based on the shape of the workpiece needs to be selected, the general processing manufacturers of bending knife shape more, especially the high degree of specialization of the manufacturers, in order to process a variety of complex bending, customized many shapes, specifications of the bending knife.

Lower mold is generally used V = 6t (t is the thickness of the material) die

There are many factors affecting the bending process, mainly the upper mold arc radius, material, material thickness, the lower die strength, the lower die mouth size and other factors. In order to meet product demand, in order to ensure the safety of the use of bending machines, manufacturers have been bending die series, we need to have a general understanding of the existing bending die in the structural design process. See the figure below, the left side of the upper mold, the right side of the lower mold.

The basic principles of the bending processing sequence:

(1) bending from the inside to the outside;

(2) bending from small to large;

(3) first bending special shapes, and then bending the general shape;

(4) the former process of molding does not have an impact on the succeeding process or interference.

The current bending form is generally shown in the figure below:

Bending radius

Sheet metal bending, in the bending at the need to have a bending radius, bending radius should not be too large or too small, should be properly selected. The bending radius is too small to cause cracking at the bend, and the bending radius is too large to make the bend easy to rebound.

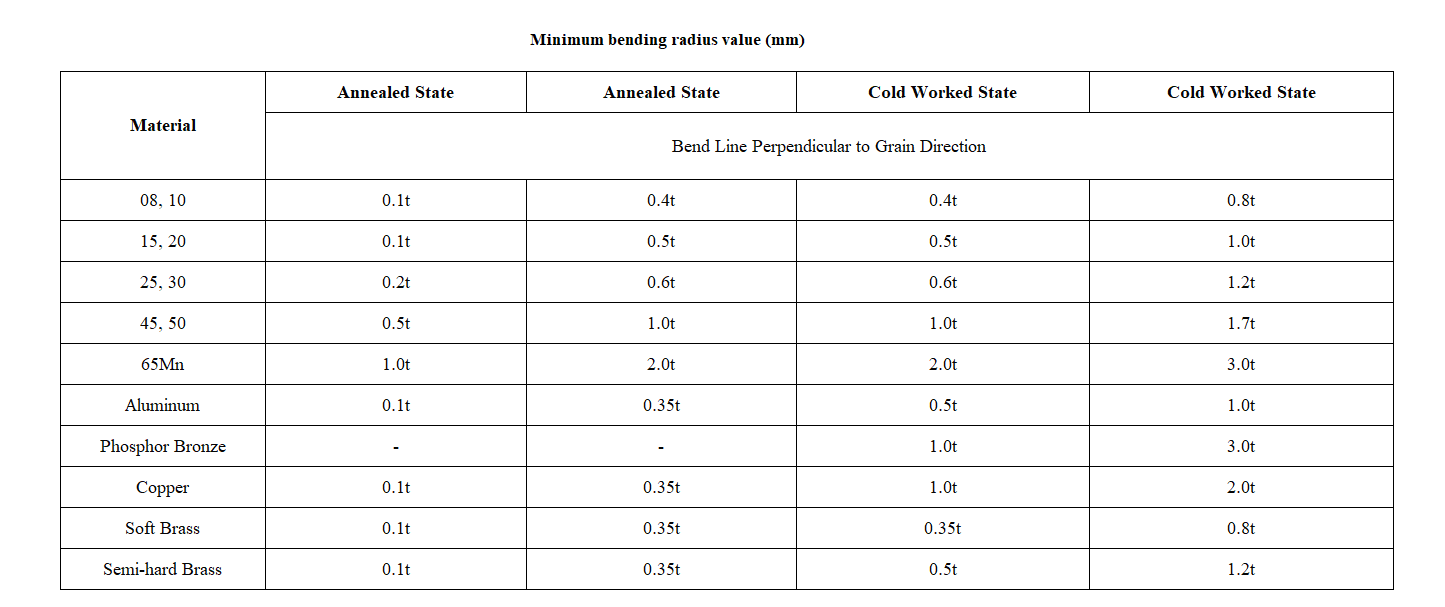

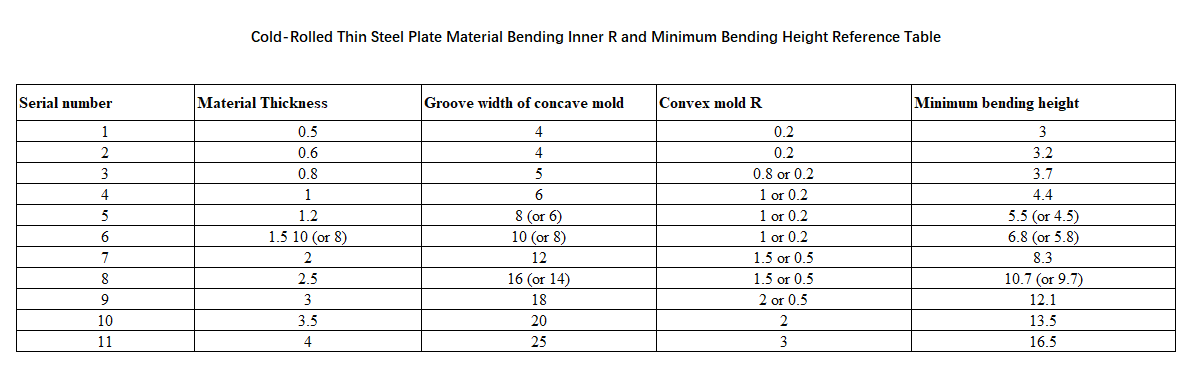

Various materials of different thicknesses of the preferred bending radius (bending radius) see the table below.

The data in the table above are preferred and are for reference purposes only. In fact, the rounding angle of the manufacturer's bending knives is usually 0.3, and a small number of bending knives have a rounding angle of 0.5.

For ordinary mild steel plate, rust-proof aluminum plate, brass plate, purple copper plate, etc., the inner rounding angle of 0.2 is not a problem, but for some high-carbon steel, duralumin, super-hard aluminum, this bending rounding angle will lead to bending breakage, or the outer rounding angle cracking.

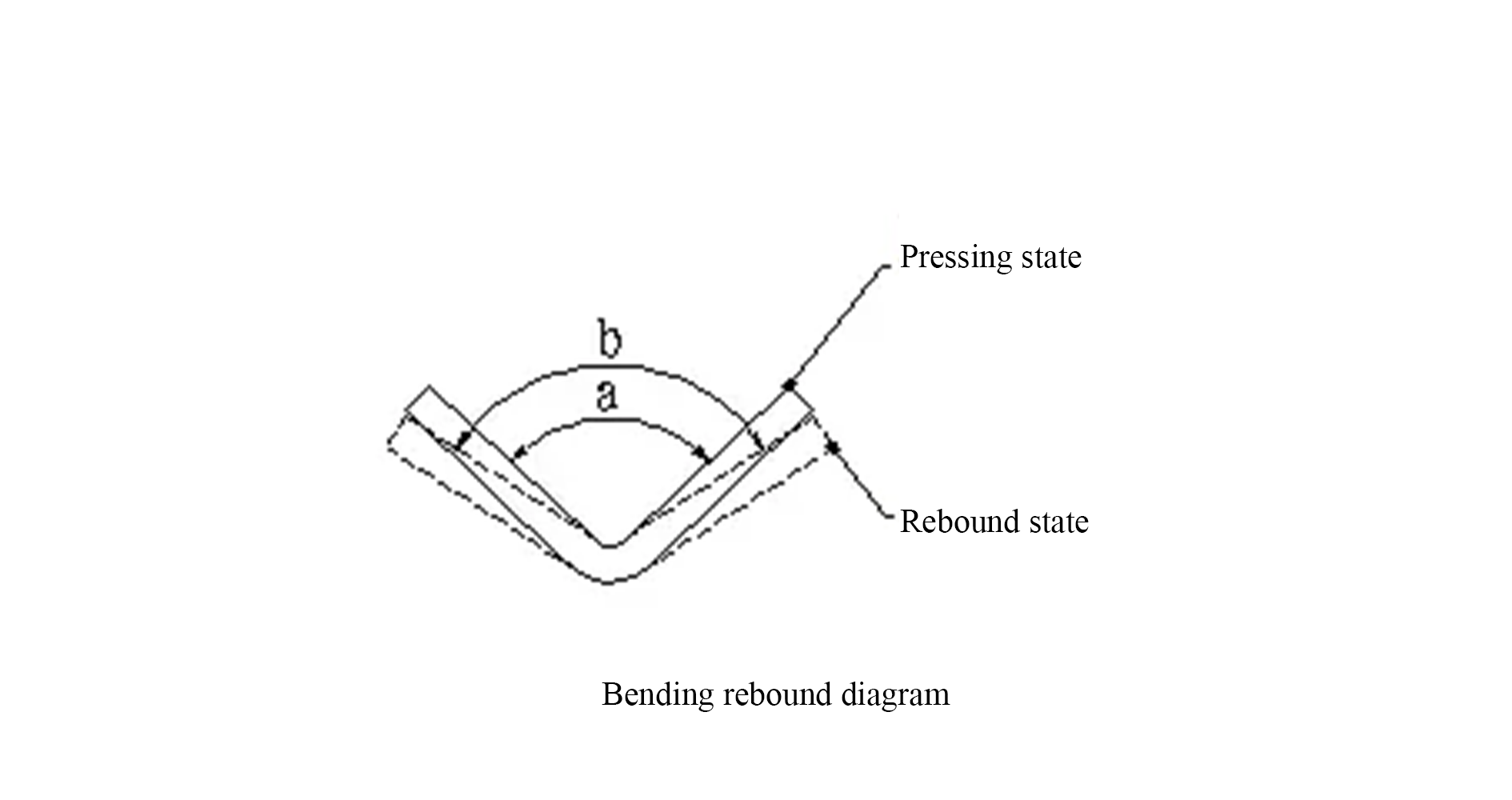

Rebound angle Δα = b - a where b - the actual angle of the part after rebound; a - the angle of the mold.

The size of the springback angle

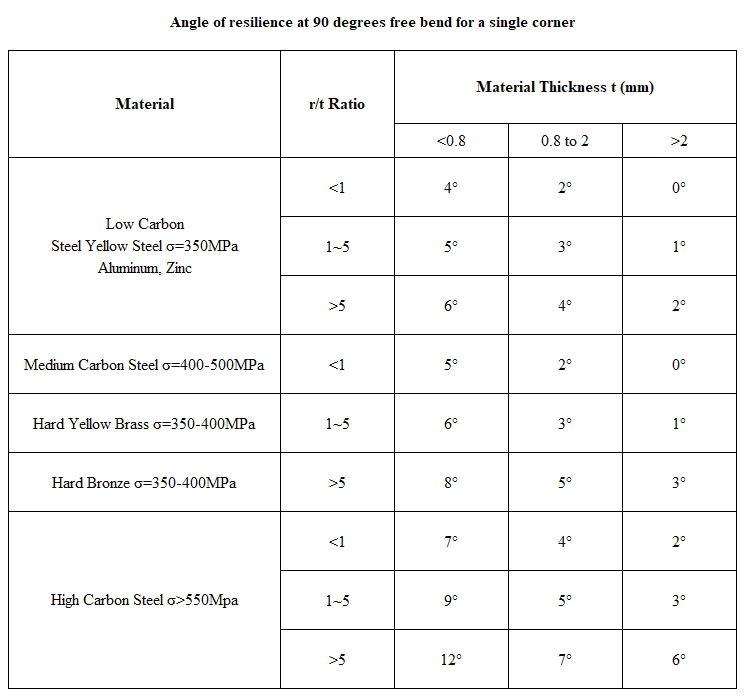

The springback angle for single angle 90 degree free bending is shown in the table below.

Factors affecting springback and measures to reduce it

(1) Mechanical Properties of Materials The size of the springback angle is directly proportional to the yield point of the material, and inversely proportional to the modulus of elasticity E. For sheet metal parts with high precision requirements, in order to minimize rebound, the material should be low carbon steel as far as possible, instead of high carbon steel and stainless steel.

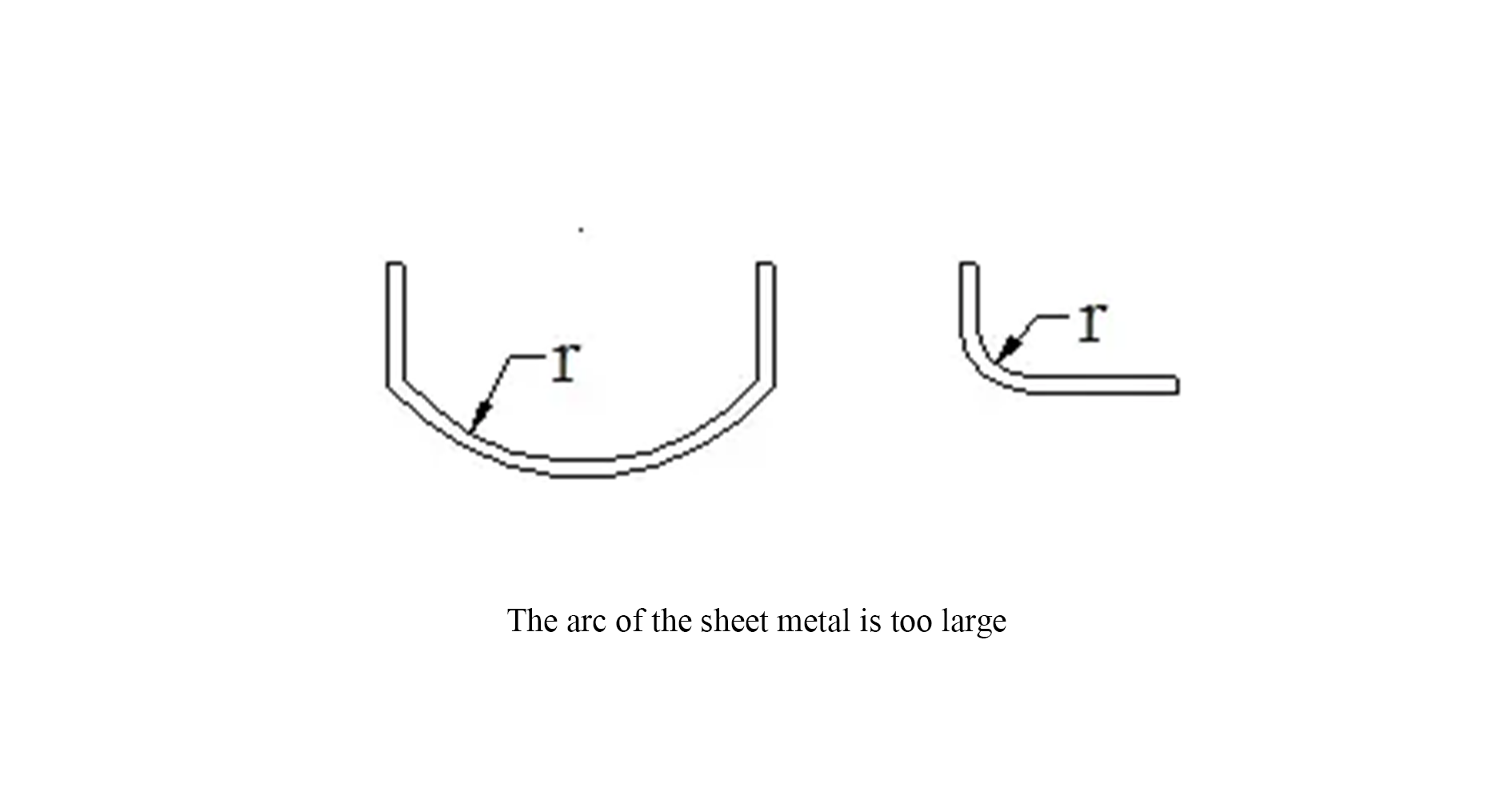

(2) The larger the relative bending radius r/t, the smaller the degree of deformation and the larger the springback angle Δα. This is a more important concept, sheet metal bending of the rounded corners, in the material properties allow, should be as small as possible to choose the bending radius, is conducive to improving accuracy. Particular attention should be paid to avoid designing large rounded corners as much as possible, as shown in the figure below, such large rounded corners are more difficult for production and quality control:

Calculation of the minimum bending edge for a single bending

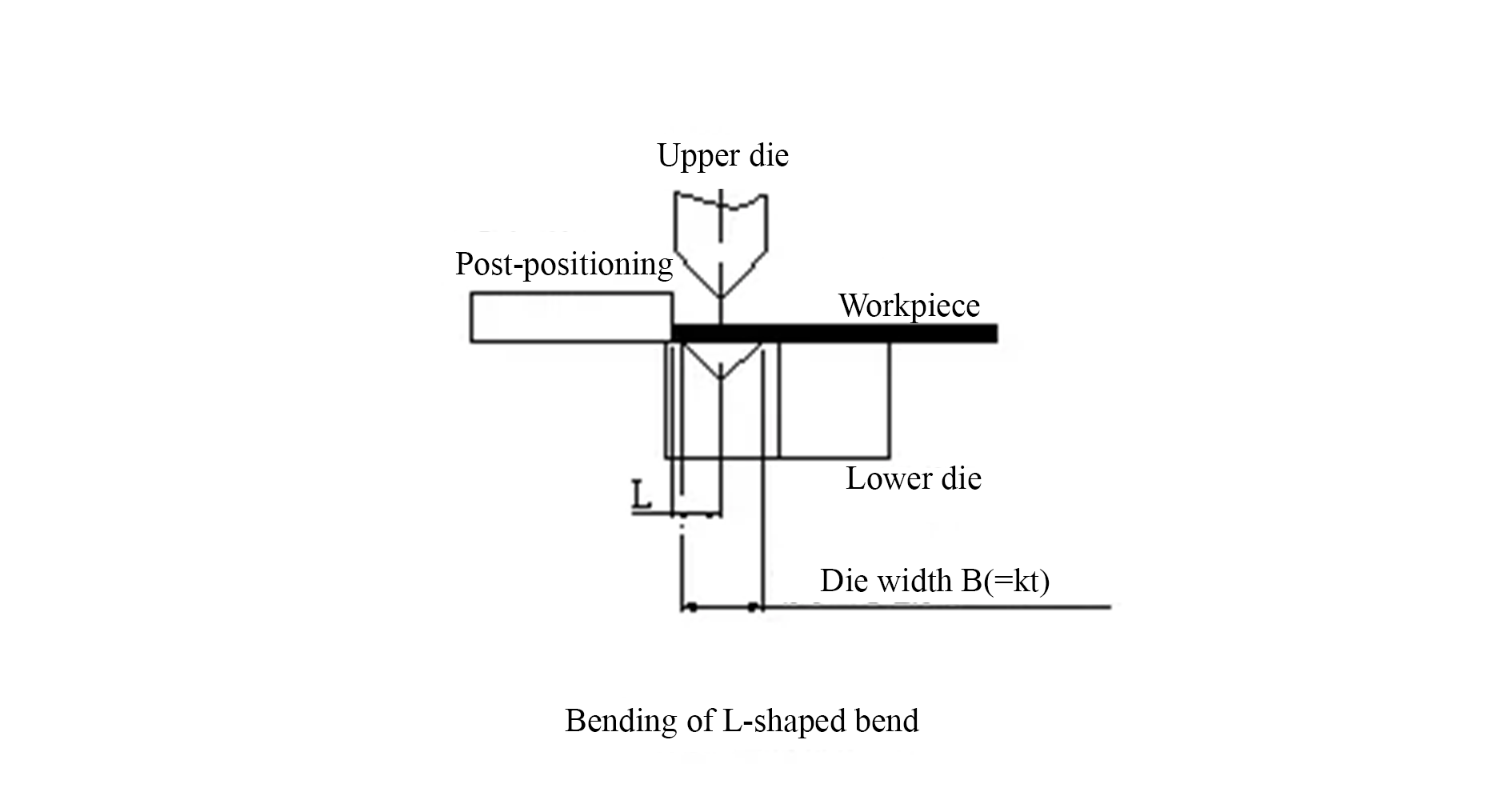

The starting state at the time of bending for L-shape bending is shown in the figure below:

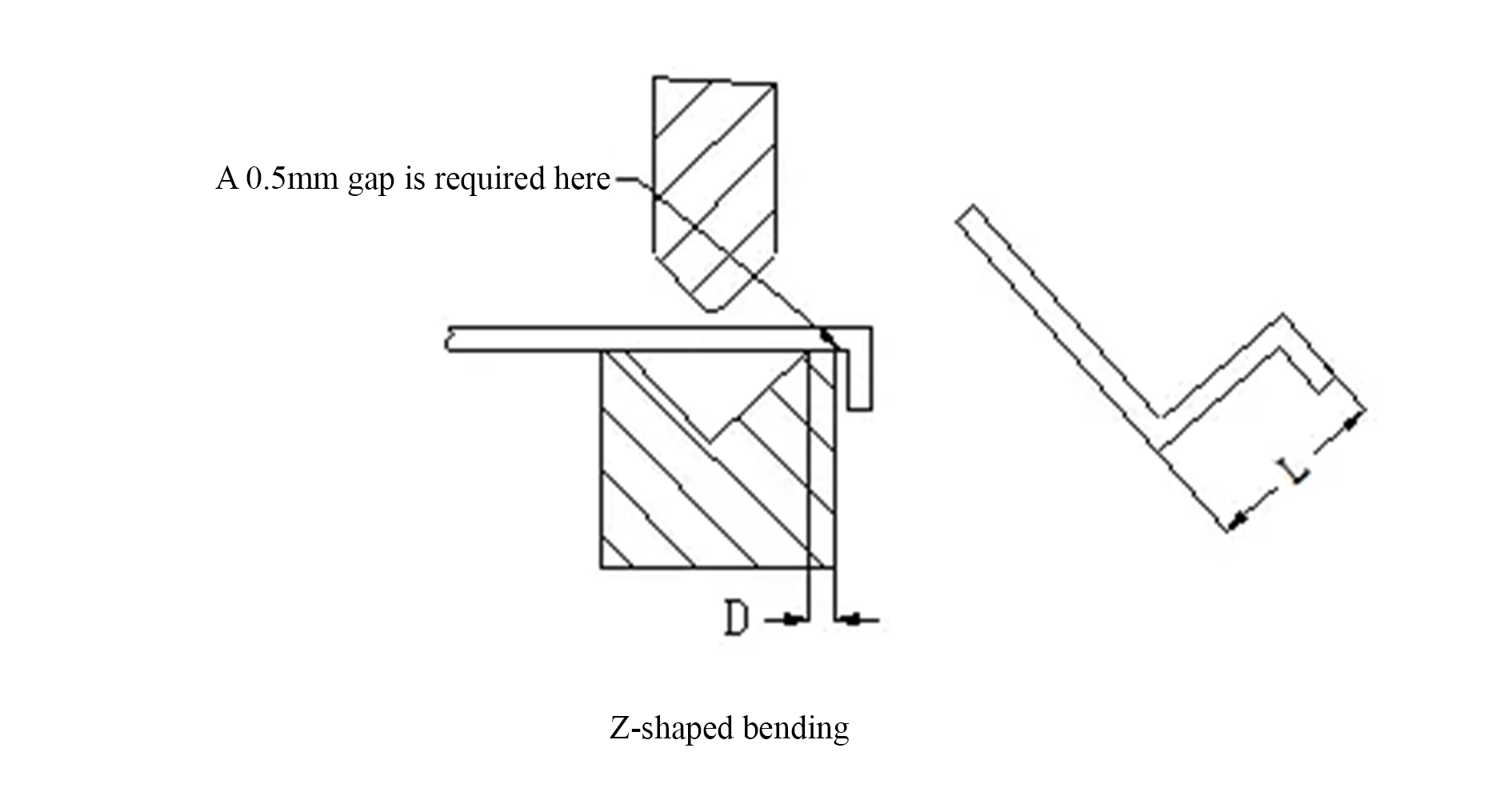

The starting state at the time of bending for Z-bending is shown in the figure below:

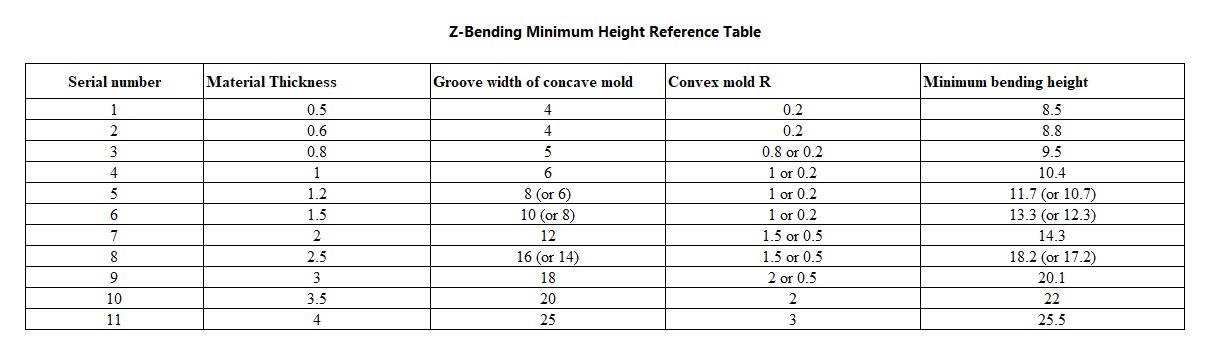

The minimum bending dimensions L corresponding to Z-bending of sheet metal with different material thicknesses are shown in the table below:

Conclusion

In summary, mastering sheet metal bending techniques is essential for producing high-quality parts efficiently. Whether using mold bending for complex, high-volume projects or machine bending for larger structures, understanding the principles, selecting the right tools, and calculating dimensions accurately are crucial for success. By considering these factors, professionals can ensure precise and consistent results, adapting to the evolving demands of the industry.